In Africa, very few people can own cars or even motorcycles and people without bicycles have to rely on inadequate and relatively expensive buses. Bicycles are creatively modified to become boda boda taxis. The United Nations Human Settlements Programme (UN-HABITAT) estimates that there are 5000 boda boda in The Earth Institute at Columbia University's Millennium City of Kisumu, the regional city in Western Kenya 27 miles from the Millennium Village of Sauri. They estimate that there are 14,000 bicycles altogether, and the number is rapidly growing. Lack of access to effective transportation is a fundamental limiter to employment opportunities, local and regional trade, and public health. A variety of NGO, perhaps most prominently The International Forum for Rural Transport and Development (IFRTD) has studied transportation issues in poor rural areas including western Kenya and has advocated a wide range of bicycle-based solutions to transport limitations.

As seen in Figure 1, bicycles currently used in Africa are utterly inappropriate for transportation in these regions. They are a throwback to the British colonial period, meant for the amusement of the wealthy classes in well-paved cities, not for critical transportation of poor rural people. They are manufactured outside Africa in China and India, and shipped complete. Despite the critical need for bicycles in Africa, there are no local bicycle building businesses anywhere in sub-Saharan Africa.

The objectives of this project are two-fold:

-

1.To build a better bike for poor Africans in rural areas

-

2.To stimulate a bicycle building industry in Africa to satisfy local needs.

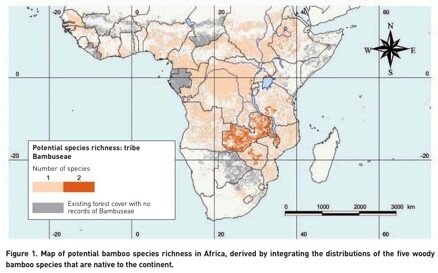

In this project, we will examine the feasibility of employing native bamboo for the bicycle frames, instead of the expensive and technically demanding carbon fiber material, or even the less expensive but also technically demanding aluminum or chromium-molybdenum steel that is commonly used to build bicycle frames. The project will contribute to some of the Earth Clinic goals by providing a necessary and viable form of transportation that will contribute to alleviation of economic and health issues.